Blogs

FEATHER MEAL

Feather meal is a by-product of the poultry industry and has been used as a feed ingredient for a long time by farmers. But used very little because the feather meal production process only produces low nutritional quality products because the keratin in feathers has not been destroyed, so it reduces the ability to digest protein of livestock and poultry.

[Vietnam Livestock Magazine] – According to the Poultry Fat and Protein Council (PPFC), a group of poultry experts under the American Poultry and Egg Export Association, feather meal is being considered a natural source of high quality protein and can be used in the diets of all livestock, not just livestock or poultry. They have the ability to replace a relatively large amount of other protein sources in the diets of livestock, poultry and aquaculture because they are a rich source of sulfur amino acids.

The current situation and reasons for not using much feather meal in animal feed

In the past, our poultry production was mainly on a small scale for consumption in the locality or neighboring provinces, but now there have been many changes, raising large-scale and concentrated. Many companies have also focused on large-capacity slaughter lines. According to the General Statistics Office in April 1, 2018 the total number of poultry in Vietnam is 300,458,200 heads, reaching an output of 600,916,400 tons/year, feathers normally account for 1-2% of body weight, so feather production Poultry can account for 12,018,328 tons/year excluding other by-products such as intestines and feces. If left untreated, a backlog of unprocessed animal by-products impedes the meat industry and poses a serious potential hazard to animals and human health.

Along with the increasing momentum of the world, our country’s poultry meat production has increased rapidly in recent years despite facing competition with imported chicken meat. Feather meal is a by-product of the poultry industry and has been used as a feed ingredient for a long time by farmers. However, the protein content of feather meal was evaluated as “perfect” in its ability to replace fish meal in many different diets. In addition, the fat in feather meal contains many fatty acids that can meet the essential energy needs of poultry feeds.

According to PPFC, feather meal has many good uses that the livestock industry has not discovered and knows how to take advantage of. This group has analyzed the value of feather meal protein in livestock and also for ruminants, in cows 2 times higher than soybean meal and confirmed, feather meal is also an appropriate source of nutrients. suitable for dairy farming. These studies have changed the position of feather meal in the animal feed market and made feather meal a valuable source of super nutrition.

As is known, the cost of feed often accounts for 70% of the cost of livestock, so finding alternative sources of raw materials with cheaper prices, especially protein sources, is very important. In recent decades, research and application of alternative protein sources have mainly focused on making use of by-products from the slaughter industry such as meat and bone meal, poultry meal, blood meal and feather meal. BLV) hydrolyzed. Compared to other animal by-products, feather feather meal is relatively cheap, although the lysine and tryptophan content is not high, but it is rich in protein and has many sulfur-containing amino acids, especially cystine. In addition to economic benefits, using BLV in animal feed also solves environmental problems when the poultry industry develops more and more. In Vietnam, the slaughter of poultry is gradually concentrated on a large scale and there have also been a number of factories that collect and process, providing BLV as a source of raw materials for feed factories.

Therefore, the potential to use BLV as a source of protein for livestock in Vietnam is very large. However, the use rate of BLV in feed of livestock and poultry needs to be evaluated to make effective use of this by-product source. Therefore, it is necessary to study the use of BLV in animal feed in the livestock, poultry and ruminant feed sectors in Vietnam.

Currently, post-slaughtering by-products are used to produce feather meal through physical and chemical processing. Feather meal has a protein content of 80-85.5%. However, the process of producing feather meal only produces products of low nutritional quality, not destroying the keratin in feathers, so the ability to digest protein is reduced. Using enzymes from bacteria has many advantages, low cost, friendly to the environment, hydrolytic enzymes

Feathers and keratinization

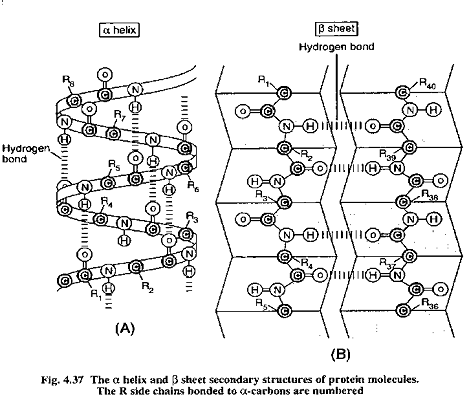

Figure 1. Feathers and geometries α(A) and β(B) keratin

Feathers cover the bird’s body, keratinized from the epithelium. Keratin is a fibrous protein that has two groups: α-keratin and β-keratin. Keratin fibers in both α and β forms twist parallel to each other to ensure fiber stability. Bird feathers have a β-keratin structure (Figure 1). Keratin is made up of amino acids, mainly glycine and alanine, keratin is insoluble in water. The stable structure of keratin is due to disulfite (S-S) bridges, making keratin difficult to digest and stable to chemical agents and proteolytic enzymes such as trypsin, pepsin and papain. Once this disulfite link is removed, feathers become useful as a cheap source of protein and are used in animal feed, aquaculture, and organic fertilizers (Hermann and Dominique, 2009). Unhydrolyzed feathers are almost insoluble in water and have a very low digestibility of about 5% (Chandler, 2007); After hydrolysis, protein digestibility is about 68-91% (Moritz and Latshaw, 2001).

Hydrolyzed feather powder production process

Chicken feathers or feathers in general could not be used as a source of protein without hydrolysis to destroy the disulfite bridges – the component that gives the unique structure in feathers.

There are many ways to convert horny materials into protein-capable hydrolyzed keratins. The most commonly used methods are hydrothermal, thermochemical and biological separation. Bioseparation is the use of keratolytic microorganisms or enzymes produced from such organisms. Keratinase-producing bacteria are mainly derived from bacteria such as Bacillus, Chryseobacterium and Pseudomonas, of which the strain Bacillus licheniformis has been tested extensively and gave good results. Using bacteria and enzymes to hydrolyze poultry feathers has the advantage of being environmentally friendly, the product obtained is hydrolyzed keratin with high quality, easy digestion and high bioavailability, maximum retention. important amino acids. However, the cost of biological treatment is too high due to the long duration of the bacteria and the high cost of enzymes.

Most industrial keratin hydrolysis processes use hydrothermal methods. Modern cooking methods cook feathers under high pressure and use steam to directly hydrolyze most of the protein, destroying the disulfite bonds. Feather meal after hydrolysis is a product with high palatability and easy digestion for all kinds of livestock and poultry. A very unique feature of feather meal is that it is high in sulfur-containing amino acids. The hydrolyzed feather meal should have at least 70% protein digested when analyzing digestibility with pepsin.

Poultry feathers are collected from the market or slaughterhouses, then put into the processing process to analyze the amino acid composition of the processed feathers compared to raw (unprocessed) feathers, the amino acids of the following feathers The hydrolysis was relatively stable, with only significant loss of cystine after steam and pressure treatment. Coarse feathers contain about 8.8% cystine protein, the feather processing has reduced the cystine content to about 3.6%, while other amino acids are very little affected.

Depending on the source of raw materials and production process, hydrolyzed feather powder is yellow to dark brown in color. The hydrolysis stage is an important step determining the quality of hydrolyzed feather meal. Oven temperature, pressure, and time are factors that can influence. Feathers must be treated with high pressure to break the strong bridges in the keratin structure. Using alkali to catalyze hydrolysis can affect amino acid quality. The temperature used is usually between 115 and 145oC or higher. The next process is that the BLV is dewatered and then dried by steam at 150oC for about 90 – 120 minutes, then crushed, sieved to remove impurities and then packaged for storage. However, depending on the ingredients in each region and the individual process of each plant, the nutritional composition may fluctuate differently according to the level announced by the manufacturer.

Composition and nutritional value of hydrolyzed feather meal used in animal husbandry

The feed value of BLV lies not only in its high protein content, but also in its energy level. For nutritionists, the relationship between energy and nutrients is very important, if the energy level of BLV is not properly assessed then its inclusion in the diet will result in an energy/protein ratio. larger and can contribute to excess fat accumulation in the body. The energy of raw materials in general and BLV in particular depends on their chemical composition, especially fat content.

Feather meal can be effectively used in animal husbandry if the balance of amino acids is taken into account. When this factor is not taken into account, studies have shown that the use of BLV at high rates often adversely affects animal performance. With this alternative, although there is a balance in protein composition (average between corn and BLV), other nutrient compositions such as amino acids will not be balanced, such as total corn lysine and BLV The sum is not equal to the lysine content in BLV, so the higher the replacement rate (4.5%), the more the imbalance in amino acids will affect the efficiency of livestock production.

Although feather meal has been produced and used in animal feed as a cheap source of protein from the by-products of poultry slaughterhouses, helping to reduce environmental pollution for many years, studies are still lacking. not much and just stopped at the beginning. The research to find out the appropriate rate of use for each type of livestock is very necessary when using this material. Therefore, it is not only necessary to pay attention to the protein content but also other factors such as fat, energy level, the balance of amino acids in feather meal materials to ensure the breeding criteria such as speed, The quality of such growth ensures the economic efficiency of livestock production.